The Secret Weapon of China's Home Appliance Supply Chain: Why 90% of German Brands Rely on the Pearl River Delta (A Deep Dive into the Unmatched Ecosystem That Powers Global Brands)

Date: 2025-04-24 Categories: FAQ Hits: 492

The Secret Weapon of China's Home Appliance Supply Chain: Why 90% of German Brands Rely on the Pearl River Delta

(A Deep Dive into the Unmatched Ecosystem That Powers Global Brands)

1. The "30-Minute Supply Chain": Why Speed & Efficiency Are Unbeatable

Key Advantage: Ultra-High Cluster Density

Within 30 minutes' drive in the Pearl River Delta (PRD), you can find:

Specialized component suppliers (motors, PCBs, injection molding)

Certification labs (CE, GS, TÜV Rheinland on-site)

Export logistics hubs (Nansha Port, Shenzhen Airport)

Real-World Example:

A German brand needed 5,000 smart coffee makers in 4 weeks for Black Friday.

PRD solution: A Dongguan factory sourced parts, assembled, and shipped in 22 days.

Alternative (Mexico/EU): Minimum 8-10 weeks at 25% higher cost.

2. "Plug-and-Play" Customization: From Prototype to Mass Production in Days

Why German Engineers Love PRD Factories?

Modular production lines: Switch between EU/US/Australia standards in 2 hours.

No MOQ traps: Willing to produce 50-100 test units (vs. 1,000+ in Turkey/India).

One-stop certification: Factories pre-certify products for CE, CB, GS, UKCA.

Case Study:

A Munich startup saved €120K by having a Shenzhen factory:

Redesign a blender for EU repairability laws (screw-in base).

Pre-load 20 language voice prompts (including Bavarian dialect).

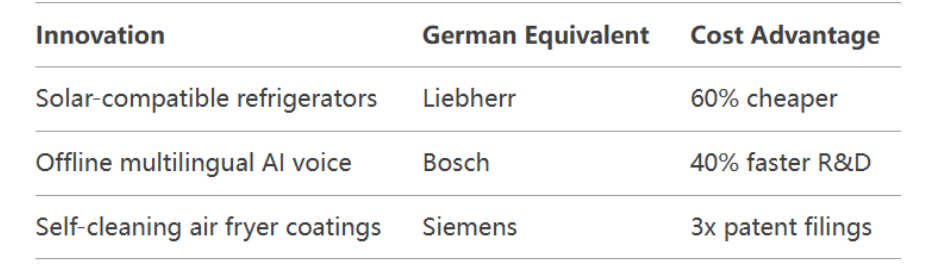

3. Hidden Champions: The Invisible Tech Behind "Made in China"

Data Point:

75% of PRD factories now have in-house German-speaking engineers (vs. 5% in Vietnam).

4. Risk Mitigation: How PRD Outsmarts Global Crises

2024-2025 Stress Tests:

1、Red Sea shipping crisis: PRD factories switched to China-Europe rail + Polish warehouses (delays cut from 60 → 18 days).

2、EU carbon tariffs: Early adopters of blockchain carbon tracking (saving 8-12% fees).

3、US tariffs: "Mexico detour" assembly lines in PRD (301 tariff avoidance).

Buyer Safety Net:

✅ Dual-supplier networks: Main factory + backup within 10km radius.

✅ Escrow payment hubs: Hong Kong banks mediate disputes in German law.

5. The German Connection: Why Bavaria ↔ Guangdong Partnerships Win

Cultural Fit Secrets:

1、Precision culture: PRD tooling shops match Swiss-grade tolerances (±0.01mm).

2、"Underpromise, overdeliver": Sample lead times quoted as 14 days, delivered in 9.

3、Beer-friendly negotiations: Guangdong bosses fluent in Oktoberfest networking.

Success Story:

A Stuttgart retailer boosted margins by 17% after a Zhongshan factory:

Customized Bauhaus-style toasters for German millennials.

Pre-loaded Alexa + Google Home + HomeKit in one device.

How to Tap Into the PRD Advantage (2026 Tactics)

For German Buyers:

1、Target "Shadow Factories":

Many Siemens/Bosch subcontractors quietly accept private-label orders.

Find them via LinkedIn (search "ex-Bosch Shenzhen") or Global Sources.

2、Demand "German-Style" Transparency:

Request live machining videos with timestamps (proves real capacity).

Insist on TÜV-certified QC checklists (same as Munich HQ standards).

3、Leverage Hybrid Logistics:

Ship semi-finished goods to EU for final assembly (avoid tariffs + speed delivery).

Free Resources for German Importers

1、PRD Factory Map: 200+ vetted suppliers with German client experience.

2、2026 EU-China Compliance Guide: Carbon tax, DPP, repairability laws.

Want More?

Reply "PRD Sourcing" to get:

Sample contracts with German arbitration clauses

List of PRD factories with ready-to-ship EU-certified designs

Why This Matters for Germany?

✅ 30% cost savings vs. Eastern Europe/Mexico sourcing.

✅ Unmatched flexibility: From 50-unit test runs to 50,000-piece batches.

✅ Future-proof: Already compliant with 2027 EU Ecodesign rules.

Product

Product  Product

Product  Product

Product  Product

Product